In this project, we will embark on the exciting journey of learning how to Make a wooden guitar for a School Project. This hands-on experience allows us to create a musical instrument and teaches us valuable skills in woodworking and craftsmanship. Learning to make a guitar fosters creativity and patience, involving various techniques and attention to detail.

The Unique Appeal of Wooden Guitars

Wooden guitars, crafted from solid and durable materials, embody the rich traditions of Pakistani craftsmanship. Their strength ensures longevity, making them reliable instruments. Building a guitar nurtures hands-on skills and creativity, and fosters self-expression and musical engagement. This project connects students to their heritage while promoting teamwork, patience, and appreciation for the artistry behind each unique piece.

Building a solid wooden guitar is a rewarding project that requires a range of high-quality materials and tools to create a beautiful, durable instrument. Here’s a detailed list to help you begin your creative journey.

How to Make a Wooden Guitar for a School Project

Before diving into the tools and techniques, assessing your skill level, budget, and workspace is important. If you’re new to woodworking, don’t be discouraged, approach the project at your own pace, and remember that practice makes perfect. Even hobbyists can succeed with dedication and attention to detail. While budget tools may be less refined, they can still yield great results. Focus on enjoying the process, confidence will grow as you learn!

Crafting Your Wooden Guitar: A Step-by-Step Guide

This step-by-step guide will equip you with the tools, materials, and techniques to build a beautiful and functional instrument.

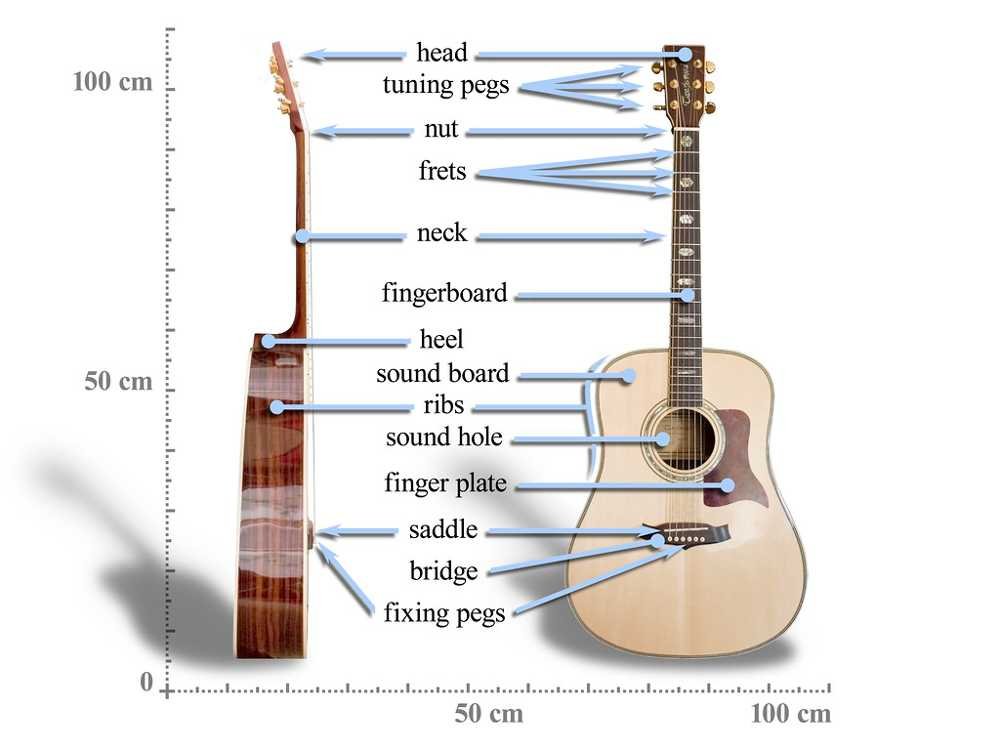

Step-1: Materials Needed for Building a Wooden Guitar

| Category | Details |

|---|---|

| A. Types of Wood | |

| Spruce | Lightweight and produces a bright, clear tone, often used for the top of acoustic guitars. |

| Mahogany | Known for its warm sound and attractive grain, frequently used for the body and neck. |

| Plywood | A more economical choice for the body, especially in beginner projects. Sturdy and easier to work with. |

| B. Tools Required | |

| Saw | Bandsaw or hand saw for cutting the wood to shape. |

| Drill | For creating holes, such as the sound hole and for tuning pegs. |

| Sandpaper | Used to smooth the edges and surfaces of the wood. |

| Glue | Strong wood glue to bond pieces together. |

| Dremel | Optional but helpful for detailed sanding and shaping. |

| C. Additional Materials | |

| Strings | Choose strings that are compatible with your guitar type (acoustic or electric). |

| Fretboard Material | Hardwood can be used for durability and aesthetics. |

| Bridge | Essential for string support and sound projection, can be made from wood. |

| Tuning Pegs | Necessary for adjusting the pitch of each string. |

Step-2: Design and Planning

Selecting the Guitar Type

Begin by deciding what type of guitar you want to build. I chose a design with a partially cut-out bottom side, which gives it a distinctive look. This choice makes the project a bit more challenging but also more rewarding.

To transfer my design to the wood, I printed out a picture, cut around it, and traced the outline onto my wood. This ensures I have a clear preference for cutting.

It’s important to measure and mark the dimensions for the body, neck, and fretboard accurately to maintain proportions and symmetry.

Step-3: Building the Guitar

Afterward, move on to shaping the neck based on your template. You’ll need to sand it further to achieve the desired contour and smoothness.

Start by carefully cutting out the guitar body shape using a bandsaw, following the design you’ve traced onto the wood. Take your time with this step; if the blade isn’t particularly thin, it’s best to make several passes instead of attempting to cut everything in one go.

Step-4: Assembling the Body

After cutting out the guitar body, it’s time to hollow out the center of one blank using the bandsaw, leaving about 1 cm around the edges. Once done, refine the edges with a Dremel for a smooth finish.

After hollowing, apply glue to the edges and press them back together, using clamps or a suitable tool to hold them in place overnight while they dry.

Step-5: Attaching the Neck

Once the body is ready, take the second blank and cut it in half lengthwise, then sand it down to about 2-3 mm thick to form the sides of the guitar.

Select one of the sides to drill a hole for the sound hole. Use a template to ensure accuracy and smooth the edges with a Dremel.

Step-6: Adding the Fretboard

Prepare the fretboard by cutting it to size and sanding it to about 1 mm thick. Mark where the frets will go with a pencil.

Use a chisel to create slight cuts for the frets, then widen these slots with a fine saw. Insert staples into the slots and seal them with super glue for added durability.

After assembling the body and neck, it’s important to sand all surfaces to create a smooth finish. This step ensures that the edges and surfaces are free of rough spots. Using a linisher can be particularly effective for achieving a professional look.

Once sanding is complete, apply a dark stain to the back and sides of the guitar, allowing it to dry overnight. This will enhance the wood’s natural beauty. After the stain has been set, varnish the front of the guitar to provide a glossy, polished appearance.

Next, focus on installing the hardware. For the bridge, cut a thin piece of wood into the desired shape. Carefully mark and drill holes for the nails, then secure them in place with glue. To finish, apply a coat of black Sharpie to give the bridge a clean and aesthetically pleasing look.

Step-7: Stringing and Tuning the Guitar

when it comes to stringing your guitar, the first step is to choose the right strings. Make sure to select strings that are compatible with the type of guitar you’ve built, paying close attention to the scale length for accurate tuning.

Once your guitar is fully assembled, proceed to attach the strings. Ensure they are tight and securely fastened; using a small amount of super glue can help keep them in place.

After the strings are attached, it’s time to tune your guitar. Carefully check each string to confirm it is tuned to the correct pitch, making adjustments as needed for a harmonious sound.

Step-8: Testing and Playing

Once tuned, strum the guitar gently to assess the sound quality. Listen for any buzzing or notes that don’t resonate well.

Familiarize yourself with basic chords and strumming patterns to start playing. Practice makes perfect, so take your time and enjoy the process!

Conclusion

Congratulations! You’ve successfully built your wooden guitar. This project not only sharpens your woodworking skills but also introduces you to the exciting world of crafting musical instruments. Now you can enjoy playing and showcasing your unique creation. Have fun making music and sharing your accomplishments with others!